1. Significance for Testing

With the increasing consciousness of environmental protection, white pollution, a new threat for environment after the green house effect, has become a focus of the whole society. As the most effective way to solve white pollution, the development and application of biodegradable plastics has drawn great attention. In order to apply various kinds of biodegradable films to packaging industry, their barrier properties need to be evaluated, especially for packaging of food, pharmaceutical and everyday-use articles. Some packaging materials have excellent barrier property that can prevent gas from entering into the package and follow-up oxidization or mildewing. On the contrary, some packaging materials have excellent gas permeability or water vapor permeability that helps gas exchange between the packaging materials. Therefore, water vapor transmission tests or gas transmission tests for various biodegradable packaging films are of great importance for property evaluation and further development of biodegradable packaging materials.

2. Starch-based Biodegradable Materials

Starch is a kind of polysaccharide compound, the widely-used natural biodegradable macromolecular compound. Starch-based plastics refer to the plastics with starch or its derivatives in ingredients, which can be further categorized into starch-filled plastics and full-starch plastics.

As to degradability, it can be categorized into starch-filled non-full-biodegradable disintegrable plastics and the full-biodegradable plastics whose main ingredient is starch-based biodegradable resin. Starch-based biodegradable packaging materials mainly include starch packaging material and raw starch & protein film packaging materials. Since starch is a kind of multi-hydroxyl natural rigid high polymer material, its defects, including moisture absorption, brittleness and difficulties to plasticization, have impeded the application of starch materials. Now, how to improve the toughness of starch-based biodegradable plastics, its moisture resistance and machinability have become the research focuses on biodegradable plastics.

At present, no specific testing standard for water vapor transmission or gas transmission property of biodegradable plastics has been issued. Thus, Labthink made a barrier property testing on full-starch biodegradable film based on ASTM D 1434(differential pressure method) and ASTM E 96 (weight method) in its Permeability Laboratory.

The sample is a full-starch biodegradable film with a thickness of approximately 380um, as shown in Fig 1. The testing instrument is Labthink PERME VAC-V2 Gas Permeability Tester and Labthink PERME W3/0120 Water Vapor Transmission Rate Tester, as shown in Fig. 2 and Fig. 3 respectively. Since full-starch biodegradable film is brittle in dry environment, it’s recommended to be stored in an environment with 50% relative humidity.

Fig. 1

Fig. 2

Fig. 3

3. Verification Tests for Barrier Property by Labthink

3.1 Gas Transmission Rate Testing

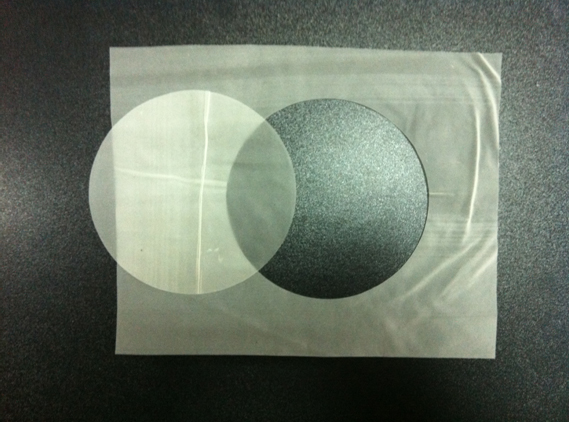

According to ASTM D1434, the specimen should be placed in the 23°C dry environment for 48 hours. High pure oxygen is needed; uniform area should be selected without wrinkles, folds, pinholes or other defaults. First, prepare, with the sampler, three pieces of samples and filter papers respectively, as shown in Fig. 4. Before placing samples, smear proper sum of vacuum grease uniformly over the area which is 2mm away from the fillister, so that the sealing performance of the system can be confirmed. Miscellaneous articles should be avoided when smearing, so as not to damage the sample. After smearing, place the prepared filter paper onto the fillister area and place the sample onto the lower testing chamber as indicated in Fig. 6., so as to realize close contact between the sample and the lower testing chamber. Install the upper chamber and screw firmly. Since starch-based biodegradable film has good gas barrier property, Proportional Mode and a Vacuuming Time of 8 hours should be selected before testing, so that required vacuum degree can be achieved. After parameter setting, press Test button and the whole testing process will accomplish automatically.

Testing result is: oxygen transmission quantity: 12.87 cm3/(m2·24h·0.1MPa)

Fig. 4

Fig. 5

Fig. 6

3.2 Water Vapor Transmission Test

Prepare samples as per ASTM E96. When cutting the samples, uniform area should be selected without wrinkles, folds, pinholes or other defaults as well as dirt or water. Prepare 3 samples (as shown in Fig. 7) with sample cutter. Clean and dry the water vapor permeation cup before placing the sample onto it. Dry state of the cup is a must. Then, fill this preconditioned cup with distilled water until water surface is 19±6mm away from the sample. Take care not to splash the water onto the thread of screw, so as not to influence the testing results. Then, place the lower rubber ring, sample, upper rubber ring and sealing ring successively into the cup, and screw the rim as shown in Fig. 8. When clamping the sample, the above-mentioned installation sequence of the cup components should be strictly followed; and the rim should be tightly screwed. Besides, when screwing the rim, be careful not to splash the distilled water out of the cup. After clamping, place the cup into the testing chamber and close the glass sealing door. It’s stipulated in the standard that testing temperature should be 38°C; the relative humidity should be 90%. Since starch-based biodegradable film has good water vapor transmission property, Weighing Interval of cups should be set at 10 minutes, and Weighing Times 4. After setting, press Test to automatically accomplish the whole testing process.

Testing result is Water Vapor Transmission Rate: 1849.079 g/(m2·24h)

Fig. 7

Fig. 8

4. Conclusions

It can be verified from the testing results that full-starch biodegradable film has excellent barrier property against oxygen, yet poor barrier property against water vapor. Thus, modification is needed if it’s to be applied as a kind of packaging material. A case in point is the full-starch thermoplastic starch, the production mechanism of which is to turn starch molecules into disorderly distributed structures, and then, forms into thermoplastic starch that has thermoplastic property. The structure of starch molecules changes, yet its chemical structure remains unchanged. Its melt between 150°C and 230°C shows, within the time of normal processing methods, chemical stability and rheological stability. Thus, it’s also called thermoplastic starch resin. The addition of nano reinforced montmorillonite into the thermoplastic starch can effectively improve its barrier property and humidity absorption resistance. Meanwhile, its mechanical properties and thermal stability can be strengthened. The complete biodegradability of full-starch plastics is of no doubt. However, owing to its high price, its popularity needs more time. The key to develop excellent starch plastics is to research on allosteric starch or thermoplastic starch.

Bibliography:

Wang Xiaoqing, Shi Fenghui, Yanqing, The Processing Technology Advances of Biodegradable Plastics Applied in Packaging

Hao Yuxin, You Wenying, Song Wensheng, Zhang Yuqing, Survey of Research on the Application of Biodegradable Starch Plastics, Feb 2006 Journal of Henan University of Science and Technology: Nature Science, Vol. 27 No. 1

Lv Fang, Zhu Guangming, Liu Daijun, Development and Application of Biodegradable Materials, July 2007 Plastic Science and Technology No.7 (Sum.183)

Website:

Baidu-Baike: Biodegradable Plastics, http://baike.baidu.com/view/270915.htm