Water vapor permeability test method is mainly divided into two categories: gravimetric method and sensor method, with the latter method being the earliest used one. Gravimetric method is the arbitration method of water vapor permeability testing. Data system of sensor method should be calibrated with that of gravimetric method.

1. Water Vapor Permeability of Materials

Water vapor permeability of materials is the main index in evaluating water proof property of packing materials such as film and sheets. This can be determined through water vapor permeability testing.

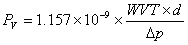

The indexes frequently used to evaluate water barrier property of materials are water vapor Transmission rate(WVT)and water vapor permeability(Pv). WVT represents the quantity of water vapor transmitting through per square meter of specimen with certain thickness within 24 hours. It is measured at a required temperature, relative humidity and vapor pressure. The unit is g/m2·24h. Water vapor permeability represents the quantity of water vapor transmitted through per unit area and per unit thickness of specimen at required temperature and relative humidity under per unit water vapor pressure within per unit time. The relationship between WVT and Pv is shown below:

Where: d represents specimen thickness, Δp is the pressure difference of water vapor on two sides of specimen, which has nothing to do with relative humidity of the two sides. The value 1.157×10-9 is used for unit transference. It is clearly stated in ASTM E 96 that the index of water vapor permeability of material is defined in accordance with gravimetric method.

2. Development of Water Vapor Permeability Test Methods

2.1 Gravimetric Method

In the middle of nineteenth century, barrier property of materials became a new index in evaluating performance of materials. The earliest permeability testing standard, ASTM E 96, was issued in 1953. This standard defines water vapor permeability parameters of materials according to the principle and parameter definition of gravimetric method. At that time, water vapor permeability testers manufactured according to gravimetric method not only required diversified accessories, complex operation, longer testing period and was lower in testing efficiency, the operators also needed strict training.

Gravimetric method at present has made obvious improvement. The newest gravimetric method water vapor permeability testers has combined testing environment and weighing condition into one, which not only improves testing accuracy of instrument and simplifies the operators' operation, but also greatly decrease the failure rate of test. At the same time, the development of weighing components and relating technology significantly improves test accuracy and efficiency of gravimetric method.

2.2 Sensor Method

Sensor method includes relative humidity method, infrared testing method and electrolytic sensor testing method, which are introduced successively since 1770.

Dynamic relative humidity method can be used for quick comparison of water vapor permeability of specimens. Moreover, its test environment is adjustable so that the actual application condition of package can be better simulated. What this method directly measures is not the Micro quantity of water vapor, but the time or speed of water vapor transmitting specimen. Therefore, data system of the tester is calibrated relying on referential film completely, which is also mentioned in ASTM E 398-03 as follows: Standard Films, which have been calibration by gravimetric means……A standard, calibration film whose WVTR has been gravimetrically determined in accordance with the desiccant method of Test Methods E96……. ISO 15106-1 also has clear specification relating the data source of referential film. It is required that the data system obtained must be in accordance with gravimetric method.

In Infrared testing method, infrared detection technology is applied to water vapor permeability testing. Electrolytic method adopts electrolytic technology for high precision testing of micro quantity water vapor. These two methods vary greatly in terms of the sensor principle but are similar in testing structure, both of which directly test the quantity of water vapor transmitting through specimen. Moreover, these two methods can test overall water vapor permeability of package. Although gravimetric method cannot give consideration to both the weighing range and test precision when test overall package, it still adopts referential film to calibrate its data system. In ISO 15106-2, it is clearly specified that referential film as well as test data should be obtained according to gravimetric means. "Reference test specimen: a test specimen whose water vapor transmission rate is known, or one for which the water vapor transmission rate has been determined in accordance with ISO 2528."

3. The Arbitration Method

Because there are several water vapor permeability test methods existing simultaneously, an arbitration method becomes necessary when a lawsuit is brought on data dispute of water vapor permeability. The arbitration method should be the basic method and needs no extra data system to calibrate its own data system. It should have scientific test technology and simple procedures. Moreover, the arbitration method should possess better data repeatability and ideal test error. Here is an objective analysis based on the characteristics of each method.

First, as stated previously, the calibration of those sensor methods needs referential film for data calibration, whether they test the quantity of water vapor transmission directly or not. Water vapor permeability data of the referential film are obtained through gravimetric method(ISO 2528 or ASTM E 96). In addition, despite the fact that adjustable infrared testing method is accepted in ASTM F 1249 conditionally (permission of relative concerns should be obtained first) as arbitration method, its data system must be calibrated through gravimetric means. Obviously, the calibrated data system of infrared method is consistent with that of gravimetric method. Therefore, if infrared method can be used as arbitration method, there is no reason that its referential calibration method, gravimetric method, cannot be the arbitration method. What is more, Micro quantity water vapor sensor adopted in sensor method belongs to the consumptive type. It should be calibrated by referential film periodically. Data systems of these sensor methods calibrated through referential film are unified data system permitting mutual substitution. But they are not qualified as arbitration test method.

Second, as far as data repeatability is concerned, the data given in several standards are very similar(ASTM E 96/E 96M-05,ASTM E 398-03 and ASTM F 1249-06). As to the test error, ASTM E 96/E 96M-05 gives such description: "This test method has no bias because water vapor transmission of materials is defined in terms of this test method." To test error of sensor method, ASTM 1249-06 gives an explanation as follows: Measured values are derived from comparisons with known-value reference films. The accuracy of this method is therefore dependent upon the validity of the values assigned to these reference films.

In conclusion, for water vapor permeability testing, gravimetric method is not only the most widely used approach, but also the arbitration method. It is the standard of those data systems obtained through other water vapor permeability test methods.