1. Gravimetric Method

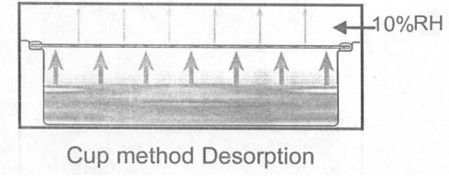

Testing principle of gravimetric method is to weigh the mass variation of the cup to which the specimen is fixed, by the analytical balances. Since transmission direction of water vapor to the cup is different, gravimetric method is further divided into desiccant method and water method, for which the testing principles are the same and testing environment are different. In desiccant method (fig.1), desiccant is put in the cup and environment of inner cup can be thought as 0% RH. Environment of Constant temperature and humidity cabinet is 38/90. In water method, distilled water and saturated salting liquid are contained in the cup. If distilled water is used, environment of inner cup can be thought as 100% and environment of constant temperature and humidity cabinet is 38/10.

Fig 1. Desiccant Method

Fig 2. Water Method

Earlier water vapor permeability tester of gravimetric method is mainly composed of three independent parts, namely cup, analytical balance and constant temperature & humidity cabinet. Testing environment and weighing environment is separated and the testing period is rather long. In 1970s, to solve the problem of long testing time, water vapor permeability tester of sensor method using infrared technology was developed. With the improvement of testing technology and accuracy of testing components, automatic testing and shorter testing time are realized in water vapor permeability tester of gravimetric method. Moreover, data stability and testing accuracy is not inferior to sensor method instrument. It is more advantageous in testing process analysis.

2. Analysis of Traditional Gravimetric Method

As a matter of fact, even if testing is carried out completely according to the procedures stated in testing standard of gravimetric method, there still exist some influencing factors. Among that, the biggest influence is the difference of testing environment and weighing environment. The cup will be put in these two environments alternatively and its movement must be completed manually, which is the main source of testing errors. On one hand, cup movement destroys the transmitting equilibrium of water vapor to specimen because of environment difference (generally, weighing is carried out in the lab and the environment is 23/50; however, testing environment of water method is 38/90 and desiccant method is 38/10). Certain time is needed to resume equilibrium. No matter how long this period is, it is not deducted from the total transmitting time, which not only prolongs the time of transmitting equilibrium, but also becomes the main source of testing error. On the other hand, cup movement depends on operators greatly; the change of operator may cause influence on testing result.

3. Improvement and Testing Breakthrough of Water Method Water Vapor Permeability Instruments

3.1 Why Choosing Water Method

Though water method is more acceptable by most professionals of flexible package, it has upper limit of weight increase (limit to testing time and water vapor transmitting quantity of specimen), which is stated in all relevant standards of desiccant method. For example, it is prescribed in standard GB 1037-1988 that moisture absorption of desiccant cannot exceed 10%. In standard ASTM E96, the increasing weight of humidity absorption is confined to 4% in the course of testing. Because desiccant is accumulation of solid (or powder), it needs slight vibration periodically for mixing during the course of testing to ensure moisture absorption ability of desiccant. This procedure must be carried out manually. Therefore, it is very difficult to realize full-automatic in desiccant method. This is because the contribution of certain amount of desiccant to control inner cup environment is limited and is unable to keep a pressure difference of water vapor at 90% RH eternally. Therefore, water method becomes the primary choice of automatic gravimetric method instruments. Water method has reduced many operations that may cause errors and can avoid cup vibration efficiently to reduce contact opportunity of inner solution and specimen. At the same time, using distilled water and saturated salted solution to control inner testing environment is stable and reliable. It can maintain a pressure difference of water vapor on two sides of specimen durably.

3.2 Base for Improvements of Water Method Water Vapor Permeability Instruments

First of all, with the development of times, the precision of gravimetric sensor has been greatly improved. Since gravimetric sensor is the core part of instruments, its improvements can directly upgrade testing accuracy of gravimetric method (desiccant method instrument and water method instrument) instrument. It can also shorten transmitting equilibrium period of testing process and can in turn shorten the whole testing time effectively. At present, resolution of gravimetric sensor adopted by Labthink TSY-T1 and T3 water vapor permeability tester is up to 0.1mg, which completely meets requirements of national standard and ISO standards.

Secondly, it can combine the temperature & humidity controlling technology and weighing technology together when designing to realize cup weighing in testing environment, by which testing process of water method is completely free from interruption of external factors. Influences caused by the above mentioned difference of testing environment and weighing environment can also be avoided. Therefore testing results becomes more accurate. A major advantage of sensor method is that testing process will not be interrupted. However, water method at present can also realize nonintervention testing and stable humidity control between two sides of the specimen.

Thirdly, popularization of computer enables the operators to control the whole process of testing through software monitor, and can automatically record valuable direct testing data through program setting with adjustable recording interval, accurate data and abundant message. Although water vapor permeability instrument of sensor method can also be operated with software, using reference film to calibrate instruments and obtain testing data with this calibrated coefficient is a premise. Moreover, what the sensor is measured and outputted directly is electric current or voltage signal, which must be transferred to become the needed data such as permeability and transmissibility. Therefore, the significance of obtaining testing data in sensor method instrument is less significant than that of gravimetric method.

3.3 Breakthrough of Improvement of Water Method Water Vapor Permeability Instrument

It is stated in some documents that gravimetric method is low in testing precision and data repeatability, and is not suitable to the testing of high water vapor permeability materials. In fact, with the improvement of water method instrument in the above-mentioned aspects, it can completely meet the testing requirements of high water vapor barrier material with very good data repeatability. Some testing data of specimen water vapor permeability tested by Labthink TSY-T1 Water Method Water Vapor Permeability Tester is listed in Table 1.

Table 1. Labthink Lab Data

| specimen | number | WVT tested data | WVT (mean) | S | CV% | ||

|---|---|---|---|---|---|---|---|

| A | 58-01 | 0.35 | 0.44 | 0.40 | 0.40 | 0.05 | 11.32 |

| B | 5E-08 | 0.96 | 0.92 | 0.92 | 0.93 | 0.02 | 2.52 |

| C | 45-04 | 1.98 | 2.07 | 2.02 | 2.02 | 0.04 | 1.75 |

| D | 67-01 | 2.40 | 2.35 | 2.45 | 2.40 | 0.05 | 2.08 |

| E | 54-03 | 3.44 | 3.30 | 3.30 | 3.35 | 0.08 | 2.42 |

| F | 5F-01 | 7.73 | 7.54 | 7.92 | 7.73 | 0.19 | 2.46 |

| G | 4E-01 | 92.28 | 91.90 | 93.04 | 92.41 | 0.58 | 0.63 |

Note: Unit of WVT is g/m2·24h

It is indicated in table one that TSY-T1 Water Vapor Permeability Tester has good performance in water vapor permeability testing with data fluctuation within 3%. Of course, uniformity of specimen has an obvious influence on stability of testing result, especially on high water barrier specimen. Moreover, for high water barrier material, even though its standard error is the same as that of other specimens, the calculated data fluctuation CV also differs greatly. For example, as to specimen A and D, the standard errors are all 0.5, but CV differs more than five times. Therefore, data fluctuation CV should be discussed with water permeability of specimen to obtain more reasonable analysis result.

4. Prospect

Water vapor permeability of material is defined by gravimetric method. Gravimetric method is very influential and is the acceptable testing method globally. It has an irreplaceable position in the field of water vapor permeability testing. Therefore improvement of gravimetric method instrument can accelerate the progressing of global water vapor permeability testing. Although sensor method instrument also develops rapidly, testing principle made it unable to separate from calibration of standard film. Moreover, it is clearly stipulated in some sensor method testing standards (such as ASTM F 1249-01, ASTM E 398-03) that the data of standard film should be tested with gravimetric method.