The content of water vapor within package can cause qualitative changes to some products. Special attention should be paid to water vapor permeability of packing materials, which will vary significantly to different materials. Therefore, water vapor permeability test becomes very important. There are many factors influencing the test of water vapor permeability, with the stability of test temperature and the humidity difference on two sides of the specimen as the most influential factors on test results.

1 The Importance of Temperature Controlling in Water Vapor Permeability Test

Most of the crystalline polymers are semi-crystalline polymer. Theoretically, crystallized part of the polymer is thought as an area that cannot be permeated during the diffusion of infiltration molecules within polymer material. It is the non-crystalline part that most of the diffusion takes place. The longer the polymer molecule chain, the more its conformation will be. When temperature increases, conformation changing of the molecule chain will be accelerated as a result of thermal motion and this in turn will decrease the extent of polymerization. Then the diffusion of infiltration molecule in the polymer is accelerated. That is to say, a rising in temperature will reduce the barrier property of material.

The permeation of water vapor to polymers is significantly influenced by temperature. Its relation with temperature can be demonstrated by Arrhenius equation.

With the rising of temperature, the coefficient of water vapor permeability increases, though the increase varies in terms of different polymer films. It is stated in some literature that the coefficient of water vapor permeability of amorphous materials increases rapidly with the rising of temperature while that of materials with certain crystallinty increases somehow slower.

2 The Influence of Humidity Difference on Test Data

Because molecules of water vapor are polarized. During the permeable process of water vapor molecules, some polymers can adsorb water vapor and appear the phenomenon of swelling, by which inner free volume will be enlarged. Water vapor permeability coefficient of materials is obviously related with the concentration of water vapor. Correspondingly, water vapor permeance is also obviously affected by humidity variation,which presents as an nonlinear relationship between water vapor permeance and the relative humidity difference to some polymer materials. For example, the relationship between water vapor permeance of hydrophilic polymer cellophane and the humidity difference does not present a liner relationship, which is the most obvious difference of water vapor and common inorganic gases in terms of permeation within polymers.

3 the Difference of Cup method and Sensor Method

At present, test methods employed by water vapor permeability are either cup method or sensor method. These methods are based on different test principles; and the structure of test instruments also varies significantly.

In cup method, the cup with specimen sealed inside is put in constant temperature and humidity atmosphere. Relative humidity on two sides of the specimen is controlled by desiccant or saturated saline solution inside the cup and by the constant temperature and humidity atmosphere. Water vapor permeability can be calculated with the measured weight increase or decrease of the cup. Test atmosphere of this method is provided by constant temperature and humidity. The humidity is the difference of inside cup humidity and atmospheric humidity. Since operations of the cup are carried out in constant temperature and humidity atmosphere before and during test, the needed volume of test atmosphere is rather big, which is not beneficial to the controlling of atmospheric temperature and humidity.

Figure 1 Principle of Cup Method

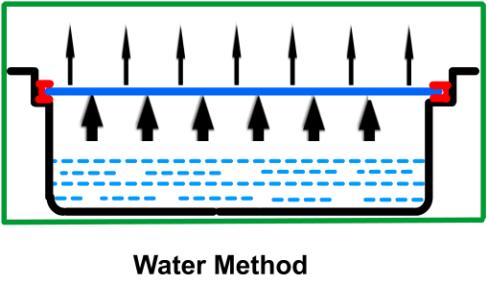

According to the type of the employed sensor, sensor method is divided into infrared sensor method, electrolyzing analysis method and dynamic relative humidity method. The former two methods are very similar in terms of test structure and test principle. In these two methods, the specimen is sealed in the upper and lower chambers. One side of the specimen maintains high humidity state with saturated saline solution while the other side keeps dry by purging dry gases. In this way, two sides of the specimen form a specific humidity difference. Water vapor transmitting through specimen into dry chamber will be carried by dry carrier gas to the sensor, where the content of water vapor is measured to determine the water vapor permeance. Instruments based on these two test principles possess better working independence and the needed volume of test chambers is very small, which make the controlling of temperature and humidity easy. Dynamic relative humidity method varies with the former two methods in terms of test principle. Temperature controlling of this method is easy to realize. However, due to its test principle, humidity difference on two sides of the specimen is constantly changing during the test process.

Figure 2. Electrolyzation Method

4 The Advantages of Sensor Method Water Vapor Permeability Tester in Temperature and Humidity Controlling

Volume is one of the main factors to realize constant temperature and humid in certain space. The smaller the volume is, the better the controlling effect of temperature and humidity will be. As stated above, instrument structure of sensor method makes the controlling of constant temperature and humidity easier to realize than cup method and can obtain ideal controlling effect with special technological treatment. Here we take Labthink TSY-W3 as an example for explanation.

Labthink TSY-W3 of electrolyzed method adopts the high precision electrolyzing humidity sensor. Its salient feature is using constant recycled water to maintain the temperature of test chamber, which is improved on the basis of temperature controlling of water bath. one thing to be noted here is that the cycle controller possesses the function of both heating and cooling with a temperature range of 0~100°C. The controlling precision is ±0.1°C, which not only meets the requirements of national and international standards, but also becomes the instrument with the most ideal temperature controlling. Using saturated saline solution to control humidity can makes the humidity on the high humidity side stable. Moreover, the low humidity side is controlled by desiccators, which can make two sides of the specimen have a very stable pressure difference with small fluctuation. The more precision the temperature and humidity controlling is, the more beneficial it is to test data. Field data repeatability of TSY-W3 is very good in the whole test range. In addition, test period of this instrument is shorter than that of cup method instruments. It presents an obvious advantage in testing materials with lower water vapor permeability. This kind of instruments is not sensitive to the environmental shaking; and has effectively avoided the influence of environment on test efficiency.

5 Conclusions

Humidity and temperature of test environment are two important factors that influence the data of water vapor permeability testing. Therefore, an effective controlling of the two factors can improve precision and repeatability of test data. Comprehensively speaking, Labthink TSY-W3 presents strong test advantages in aspects of temperature and humidity controlling.