In recent years, R&D and QC specialists in pharmaceutical industry are paying more and more attention to the seal integrity of pharmaceutical packages.

Package integrity testing, as one safety requirement for pharmaceutical packages specified both in USP 1207 and China GMP for sterile pharmaceuticals 2015, aims to study the water, oxygen or microorganism penetration and avoid contamination or loss of the medicine under such circumstances.

Leakage ratio is the key.

Strictly speaking, leakage may occur to all pharmaceutical packages. If the medicine is very sensitive to oxygen or moisture, its package must be required an ultra-low leakage ratio to maintain and ensure its stability and shelf life.

Blister pack is the most used packaging type for capsule, tablet and other small-dose medicine in pharmaceutical industry. Medicine is packed in the cavity of a rigid backing and then sealed with aluminum foil to form the blister pack. The damage or leak of one cavity will not affect the integrity of other cavities, so it needs to check the leak and seal integrity of each cavity.

Recently, our photographer shot a short video of a couple of blister pack leak testing. It catches the crucial moment of blister pack leak test.

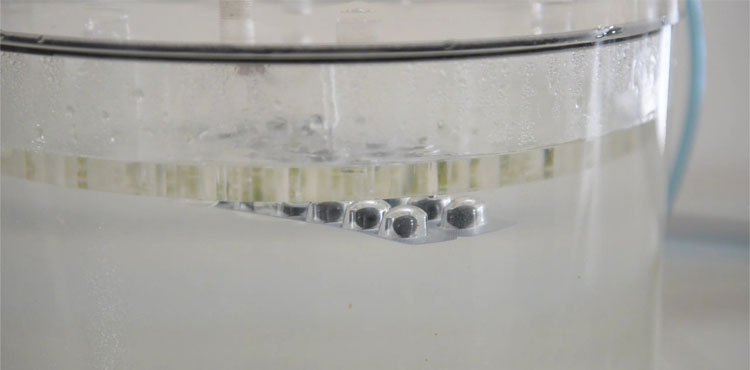

We checked the leaks by bubble emission used Labthink MFY-01 Leak Tester. ①Submerged the blister pack specimens into the water within the vacuum chamber。②set the cover on the vacuum chamber, close the outlet valve and turned on the vacuum to a selected vacuum level. ③during the rise in vacuum, observed the submerged blister packs for the leakage in the form of a steady progression of bubbles. We tested five blister packs and only one have good seal integrity, the other four leaked at the sealing edges at pressure 31.5 KPa,-70.0 KPa, -26.9 KPa and -43.1KPa.

Sometimes, Methylene blue can be used as the medium fluid to check Seal integrity of pharmaceutical package using the same method.

Also, we have another way using internal air pressurization method to check the seal integrity of packages, bottle caps, lidding of flexible tubes and so on. Different from the gross leak using the method above, the method can quantitatively leaks by pumping air into the specimen. Videos will be available soon to show the detailed testing procedures.